ISU SAE BAJA

Controls + Sponsorship Lead

Research and Development:

From the year before, we dug deeper into these things for answers.

- Compared 2mm vs 3mm rotors and affected weights – 33% weight decrease

- Compared existing caliper options and manufacturing between PS1s and

- GP200s for custom caliper design

- Researched various off the shelf master cylinders and noted displacement and piston sizes to determine fluid displacement – cylinder displacement clears necessary amount by .46 oz.

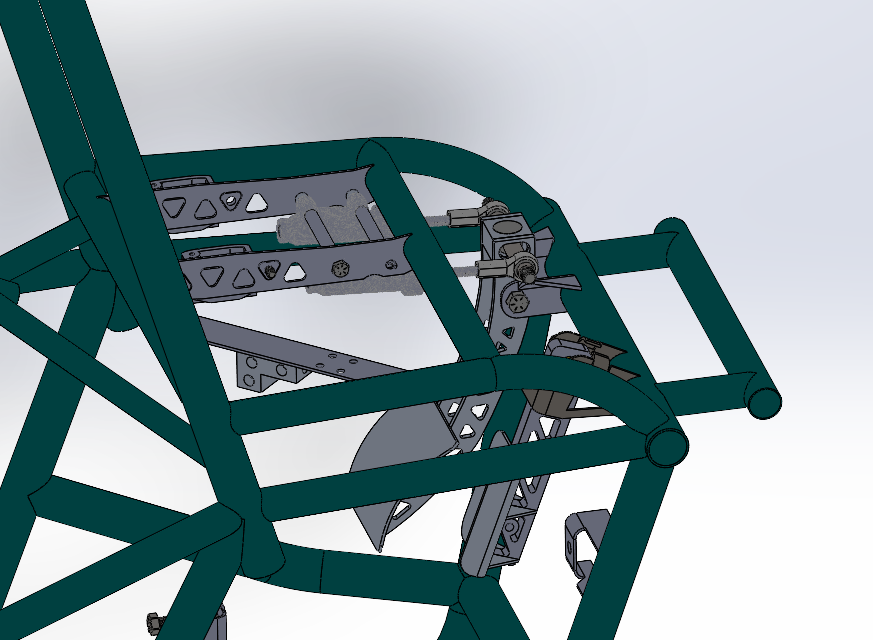

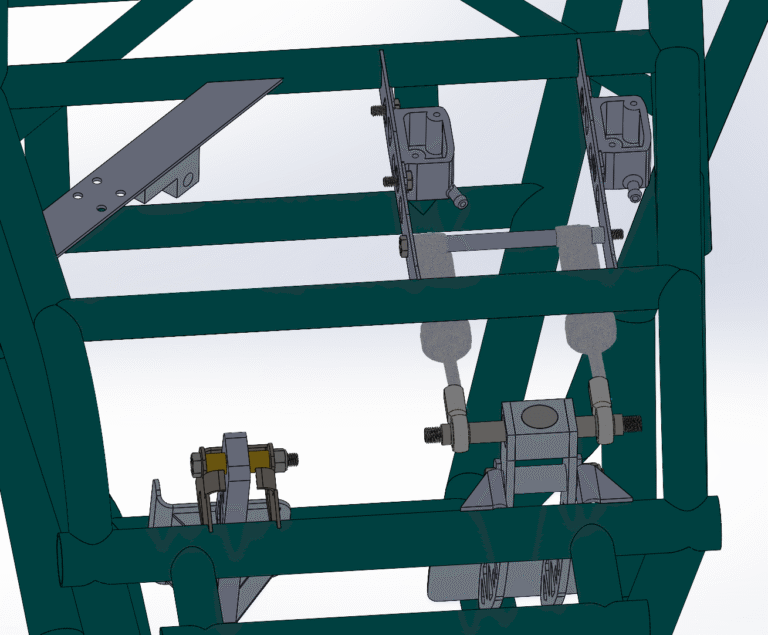

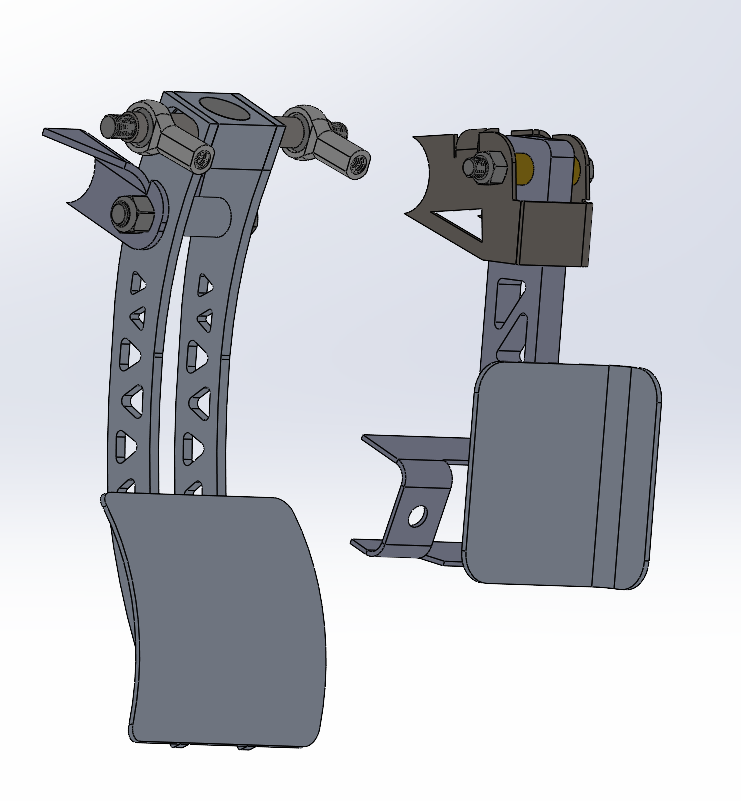

Design and Cad

Data Collection

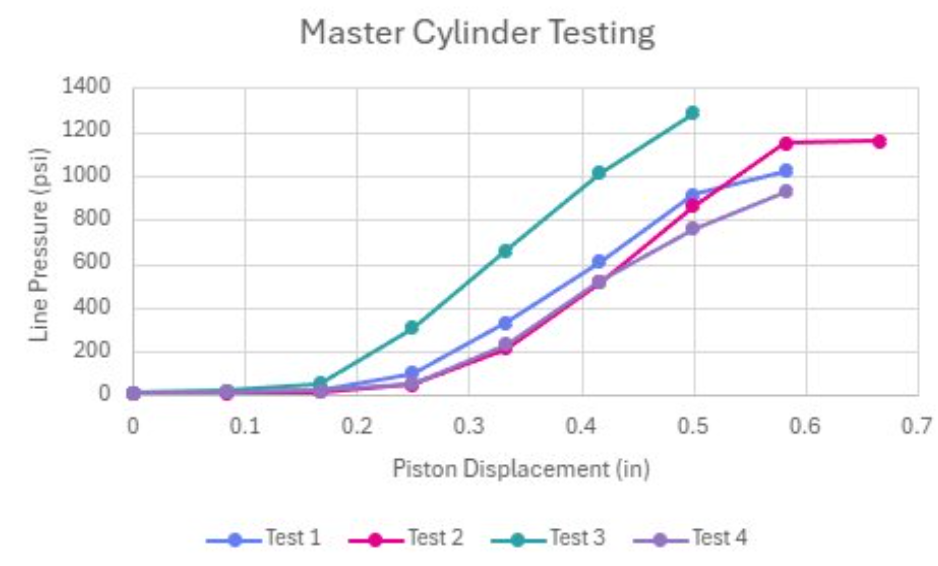

- Checking pressure requirement based off hand calculations

- Fluid displacement for master cylinders

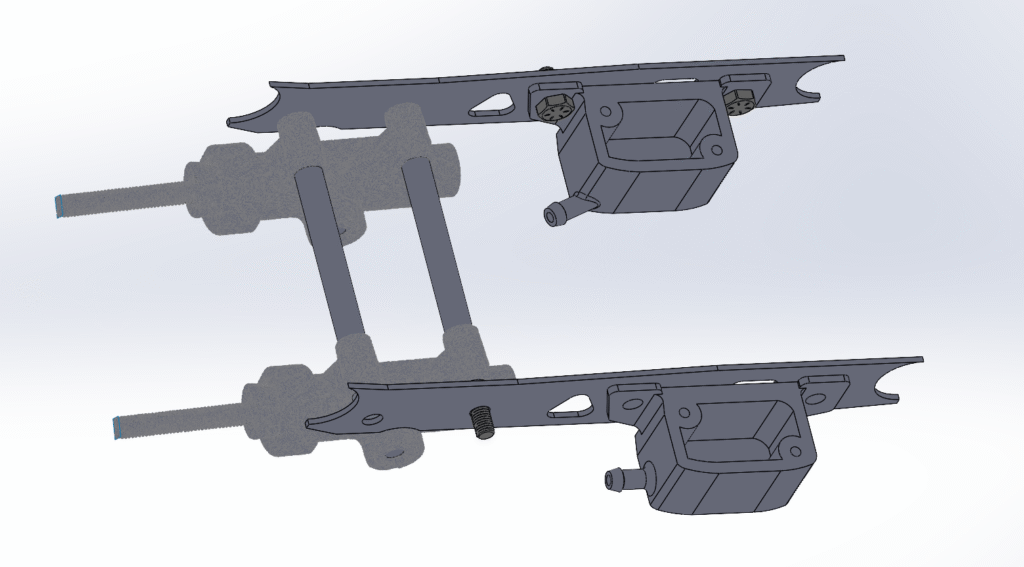

- Rev 1 testing – 1189 PSI required for full lock

- 60% front axle weight transfer assumed from 2024

- Rev 3 testing – 1281 PSI required for full lock

- 83% front axle weight transfer adjusted for 2025

vehicle

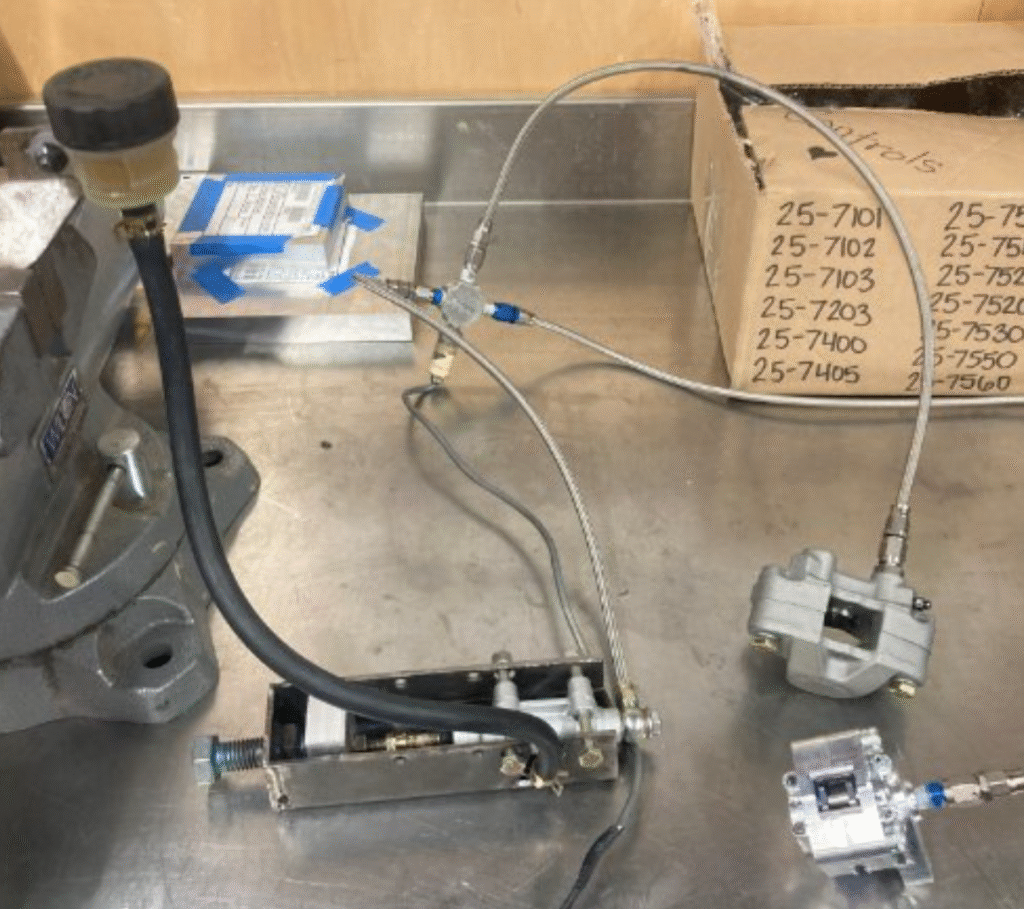

The test block above holds the master cylinder in place. On the end, there is a bolt that can be turned to compress the cylinder, allowing us to see the maximum amount of PSI in the line under maximum compression, which was 1298 PSI, covering our necessary PSI based off calculations at 1281.

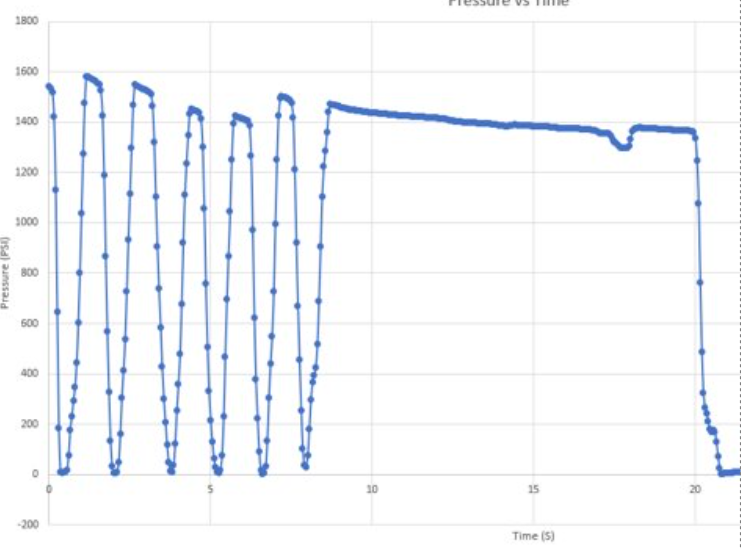

We also tested the maximum line pressure with the small masters and custom calipers on the car, reaching a maximum of roughly 1600 PSI. This should have been plenty, however this was done while pumping the brakes. After researching, this number would have been artificially increased. As the brakes are pumped, the line pressure will increase as the liquid will compress further on its own when being compressed and released over and over. This led to our fault before competition, realizing the custom calipers would not suffice with the current master cylinders.

Correlation of Analysis and Testing

Arriving at the competition, we had to place the larger cylinders on to generate the line pressure needed. Here is why we could not generate enough pressure:

- Pumping Brake lines is the reason why the psi is higher in the

testing section over the master cylinder test. - CG height may not be accurate

- Deflection in the caliper

- Brake pad selection

- Improper Bleeding – larger issue to fix for next year

Which are all obstacles to be overtaken by me this year!

Sponsorship Lead

Business Presentation:

My main focus this year was the business presentation. Historically, Iowa State has not been amazing at the business presentation, placing 34th in the competition before me. We jumped to 17th in the next competition which was a huge improvement from the year before. To do this, I focused on 3 things:

- Taking Action – The judges want to see a real, thought out product. Think deeper and make it marketable.

- Clarity – Going in deeper about cost reports and manufacturing helped to cover a lot of clarity issues with the backend of vehicle production.

- Visuals – Spending time on the actual presentation made it much more appealing to the audience, boosting interesting and leading to a stronger emphasis on what ISU BAJA can do.

Blender:

Focusing on the visuals, I made it my task to learn blender and implement it into our presentation. Though it can be difficult to learn, it is the same idea as solidworks; you have to play with it before a while before it clicks. I made visuals for each of our different products rolling into action as well as the final clip you see on the left. I plan to deepen my skills this fall for the next business presentation to come.

Sponsorship Packet:

My last major focus was our packet. Having an outdated packet is not what gets eyes on your time. With that being said, I refurbished our packet to be updated for this year, obtaining a new sponsor (3D Connexion) before officially taking my role during the summer of 2025 as the sponsorship lead.

Tyler Hall is proudly powered by WordPress